SP1壓敏紙在顯示屏制作中點ACF工藝設備

3C產品電流測試線纜測試應用

三合一假SIM卡托在生產過程中的測試應用

采用SPI壓敏紙用于微小重力沖擊試驗過程

壓合設備對手機屏幕壓合的工作過程

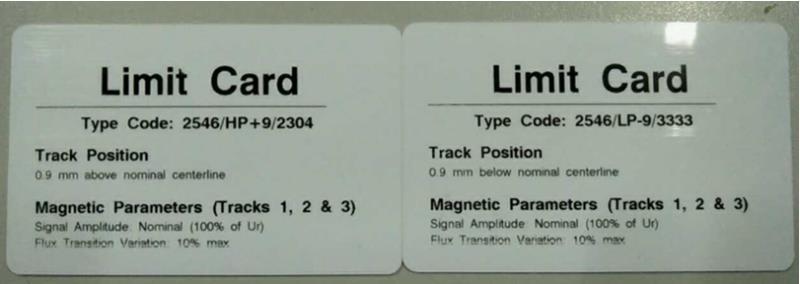

Limit Card在POS生產過程中的測試應用

塑膠取卡針在通訊產品制造過程中的品質改善

SP1壓敏紙測試鞋底壓力分布的過程測試

SP1壓敏紙穿戴設備組裝過程中的應用

SP1壓敏紙在手機電池組裝過程中的應用

POS生測試應用產過程中的,需要對磁頭的位置進行標定驗證,設備在實際工作中,因為人為因素可能造成浮高或者過低,這將考驗磁頭的讀寫能力,

LIMIT CARD根據實際生產狀況,模仿實際工況,考驗對POS機的工作過程進行驗證,

| LIMIT CARD在POS生測試應用產過程中的 |

|

以下是原始參考資料

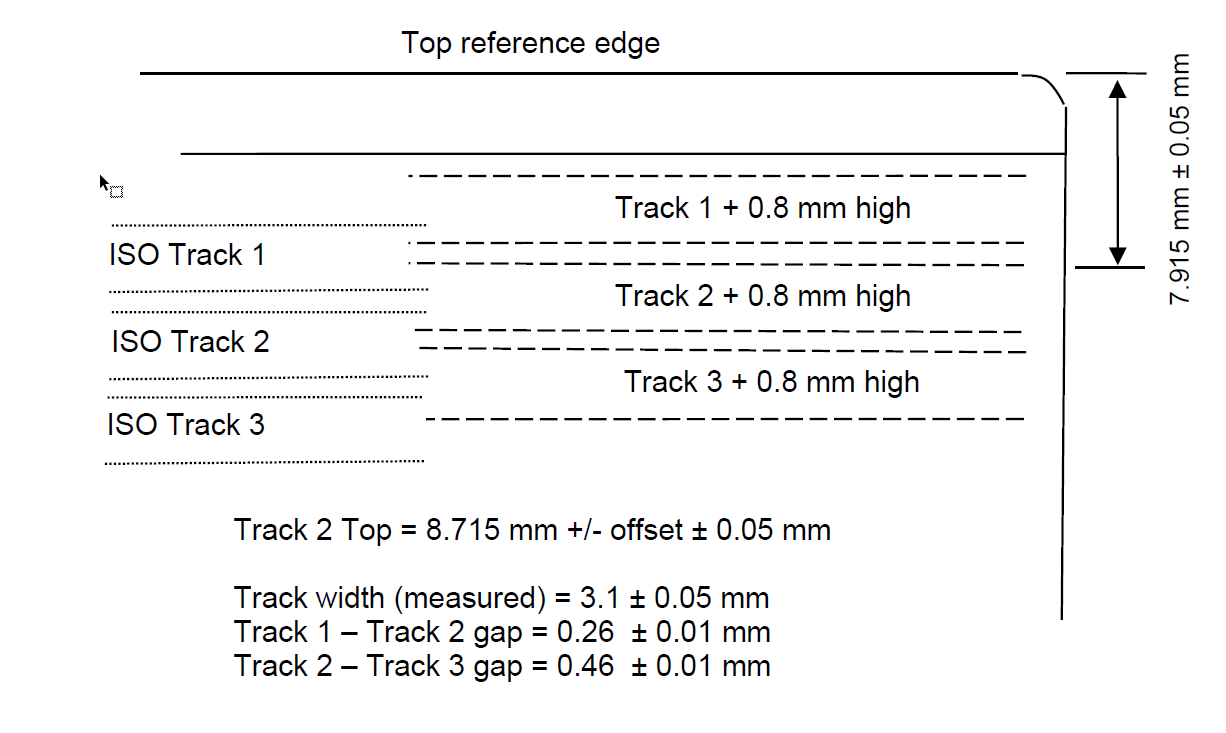

Track Location Cards-Accuracy/Precision Note

When we produce a Track Location Card which places the tracks, for example, at 0.8mm above the ISO centerline. we check the actual placement of the tracks in thefollowing way:

1. Apply magnetic viewing fluid on the magnetic stripe permitting a visual examinationof the encoded flux transitions.

2.A measuring microscope equipped with X & Y digital calipers with a instrumenterror of+ 0.003 mm.

3.The hairline of the microscope is targeted at the top reference edge of the card and theX caliper zeroed. The microscope stage is moved by means of the X caliper until thehairline is positioned at the top of the flux transitions on Track 2. We only measurethe top of Track 2 since the track width and other track positions are fixed (three trackhead). See below for head dimensions and measured distances

Note: Several accuracy & precision factors:

The magnetic viewing fluid make the magnified flux transitions appear somewhat fuzzyand thus it is the microscope operator's judgment of where the tops of the flux transitionsare positioned. Part of what makes the flux transitions fuzzy is fringing from theencoding head. The three track encoding head track widths are stated as 0.110 + 0.003inches (2.794 +0.08 mm). Fringing effects cause the appearance of the flux transitions tomeasure 3.1 + 0.05 mm. The extent that the magnetic viewing fluid can be attracted to thedecreasing magnetic field in the fringe portion is a factor on where the flux transitions areviewed.

Key dimensions:

Track 1, 2 or 3 width (head): 2.794 0.08 mmTrack 1, 2 or 3 width (measured): 3.06 + 0.05 mm

Gap between Track 1 and Track 2 (measured): 0.26 0.01 mmGap between Track 2 and Track 3 (measured): 0.46 +0.01 mm

Encode head moves laterally on stepper motor under software controlHead offset precision: 0.025 mm per step

Measured track position and expected tolerances from a Track Card with a 0.8 mm abovethe ISO centerline is shown on the next page.

Example of a 0.8 mm high track offset card: 8.715 mm - 0.8 mm + 0.05 = 7.915 + 0.05mm

電 話:137-5119-6353

電 話:137-5119-6353

手 機:138-2999-7590

手 機:138-2999-7590

電 話:137-5119-6353

電 話:137-5119-6353

手 機:138-2999-7590

手 機:138-2999-7590

|工業測量膠片 | 測量儀器 | 自動化設備 | 精密治工具 | SP1壓敏紙 | SP2壓敏紙 | SP3壓敏紙 | LW壓敏紙 | LLW壓敏紙 | LLLW壓敏紙 | 4LW壓敏紙 | 5LW壓敏紙 | HHS壓敏紙 | UV感光紙 | 感溫熱敏紙 |

東莞市穩健科技有限公司 版權所有 ? Powered by wingiant.net

投訴.建議.友鏈交換和訂閱我們,請發電郵到: